Frequently Asked Questions

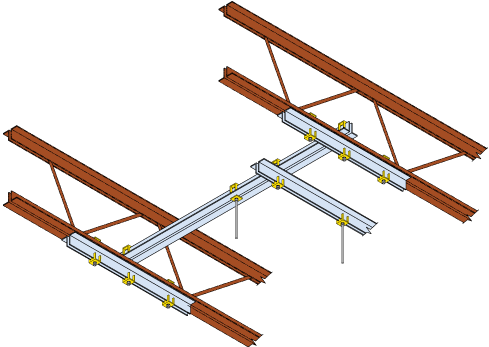

What are the advantages of suspension clamps?

The advantages of suspension clamps include their ability to safely suspend loads of up to 4,000 lbs distributed load capacity without the need for welding or drilling, offering flexibility for equipment relocation and ensuring ease of installation and use in various applications.

How do suspension clamps work effectively?

Suspension clamps work effectively by securely supporting loads through a simple, adjustable mechanism that eliminates the need for welding or drilling. This allows for quick installation and easy relocation of HVAC equipment and ceiling fixtures.

What materials are used for suspension clamps?

The materials used for suspension clamps typically include high-strength steel and durable coatings, ensuring they can support heavy loads while resisting corrosion and wear. These materials provide both reliability and longevity in various applications.

Can suspension clamps support heavy loads?

Suspension clamps can indeed support heavy loads. Specifically, the Suspension Clamp System from Chicago Clamp Company is designed to safely suspend loads of up to 2,000 lbs without the need for welding or drilling.

What applications benefit from suspension clamps?

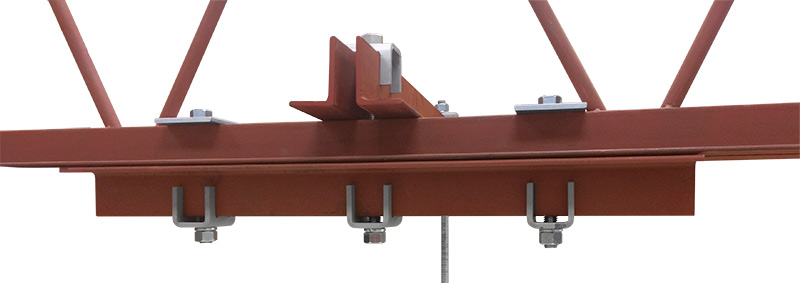

The applications that benefit from suspension clamps include HVAC installations, ceiling fixtures, and various overhead equipment setups. These clamps offer a flexible, efficient solution for safely suspending loads without the need for welding or drilling.

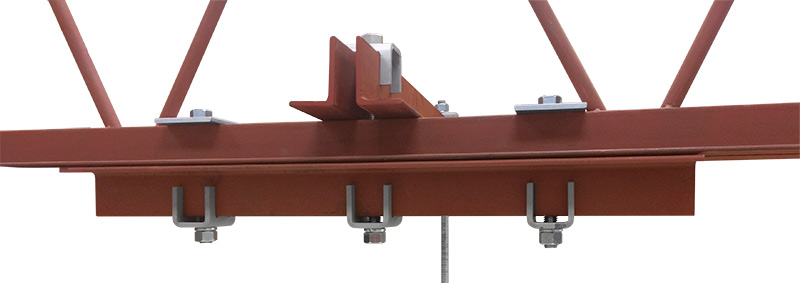

How to install suspension clamps correctly?

Installing suspension clamps correctly involves positioning the clamps securely on the designated support structures, ensuring they are level and aligned. Tighten all fasteners according to the manufacturer's specifications for optimal load support and safety.

What is the lifespan of suspension clamps?

The lifespan of suspension clamps is typically extensive, often exceeding 10 years with proper installation and maintenance. Factors such as environmental conditions and load weight can influence their durability.

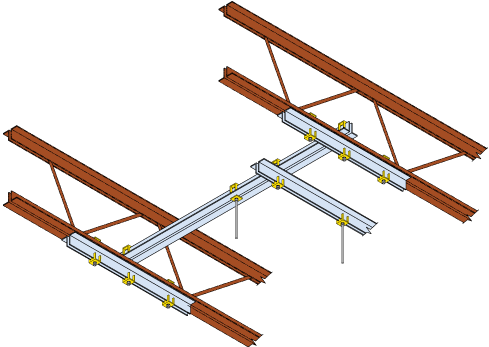

Are suspension clamps adjustable for different heights?

Suspension clamps are adjustable for different heights, allowing for flexible installation and easy adaptation to various applications. This feature ensures that equipment can be securely suspended at the desired elevation without the need for welding or drilling.

What safety features do suspension clamps have?

The safety features of suspension clamps include robust load-bearing capabilities, ensuring secure suspension of up to 2,000 lbs, along with a design that minimizes the risk of accidental disengagement, providing peace of mind during installation and use.

How do suspension clamps compare to traditional methods?

Suspension clamps offer a more efficient alternative to traditional methods by eliminating the need for welding or drilling, allowing for easier installation and relocation of equipment while safely supporting loads of up to 2,000 lbs.

What industries commonly use suspension clamps?

The industries that commonly use suspension clamps include HVAC, construction, electrical, and plumbing. These sectors benefit from the clamps' ability to securely suspend equipment and fixtures without the need for welding or drilling.

How to choose the right suspension clamp?

Choosing the right suspension clamp involves considering the load capacity, installation environment, and flexibility for future adjustments. Ensure the clamp can safely support your specific equipment while allowing for easy relocation as needed.

Can suspension clamps be reused after installation?

Suspension clamps can indeed be reused after installation. Their design allows for easy disassembly and relocation, making them a flexible solution for various applications without compromising their integrity.

What are common issues with suspension clamps?

Common issues with suspension clamps include inadequate load capacity, improper installation leading to instability, and corrosion over time if not made from durable materials. Regular inspections and proper usage can mitigate these problems.

How do suspension clamps improve installation efficiency?

Suspension clamps significantly improve installation efficiency by allowing quick and easy setup without the need for welding or drilling. This flexibility reduces labor time and costs, enabling faster adaptations and relocations of HVAC equipment and ceiling fixtures.

What certifications should suspension clamps have?

The certifications that suspension clamps should have include compliance with industry standards such as ASTM, UL, and ANSI. These certifications ensure safety, reliability, and performance in supporting HVAC equipment and ceiling fixtures.

How to maintain suspension clamps over time?

Maintaining suspension clamps over time involves regularly inspecting them for signs of wear or damage, ensuring all connections are secure, and cleaning any debris that may accumulate. This will help ensure optimal performance and longevity.

What is the weight limit for suspension clamps?

The weight limit for suspension clamps is up to 2,000 lbs. This allows for safe and secure suspension of HVAC equipment and other ceiling fixtures without the need for welding or drilling.

How do suspension clamps enhance system flexibility?

Suspension clamps enhance system flexibility by allowing for easy installation and repositioning of HVAC equipment and ceiling fixtures without the need for welding or drilling. This adaptability enables users to modify layouts efficiently as needs change.

What tools are needed for suspension clamp installation?

The tools needed for suspension clamp installation include a wrench for tightening, a drill for any necessary adjustments, and a level to ensure proper alignment. These basic tools facilitate a straightforward and efficient installation process.

How do suspension clamps reduce installation time?

Suspension clamps significantly reduce installation time by eliminating the need for welding or drilling. Their easy-to-use design allows for quick adjustments and relocations, enabling faster setup and minimizing labor costs.

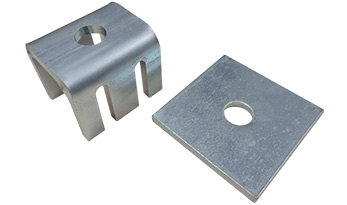

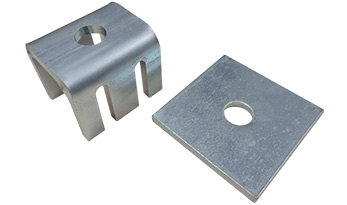

What are the design features of suspension clamps?

The design features of suspension clamps include robust construction capable of supporting loads up to 2,000 lbs, a versatile system that eliminates the need for welding or drilling, and ease of installation for quick adaptability in various applications.

How do suspension clamps prevent equipment damage?

Suspension clamps prevent equipment damage by securely supporting heavy loads without the risk of welding or drilling, which can compromise structural integrity. Their design allows for even weight distribution, minimizing stress on equipment and ensuring safe, stable installations.

What innovations exist in suspension clamp technology?

Innovations in suspension clamp technology include advanced materials that enhance strength and durability, as well as designs that allow for quick installation and adjustment without welding or drilling, providing greater flexibility for various applications.

How to troubleshoot suspension clamp installation problems?

Troubleshooting suspension clamp installation problems involves checking for proper alignment, ensuring all components are securely tightened, and verifying load capacity limits. If issues persist, consult the installation manual or contact customer support for further assistance.

What are the environmental impacts of suspension clamps?

The environmental impacts of suspension clamps are minimal, as they eliminate the need for welding and drilling, reducing waste and energy consumption during installation. Their reusable design also promotes sustainability by allowing for easy relocation and adaptation of equipment.

How do suspension clamps affect HVAC performance?

The impact of suspension clamps on HVAC performance is significant. By securely suspending equipment without welding or drilling, they enhance system stability and efficiency, reduce vibration, and allow for easier maintenance and adjustments, ultimately leading to improved overall performance.

What are the best practices for using suspension clamps?

The best practices for using suspension clamps include ensuring proper load distribution, regularly inspecting clamps for wear, and following manufacturer guidelines for installation. This ensures safe and effective suspension of equipment without compromising stability.