Frequently Asked Questions

What are the benefits of the Upper Deck Fall Protection Anchorage system?

The benefits of the Upper Deck Fall Protection Anchorage system include enhanced worker safety, easy installation, and effective load transfer, making it an ideal solution for construction environments where fall protection is critical.

How is the Upper Deck Fall Protection Anchorage installed?

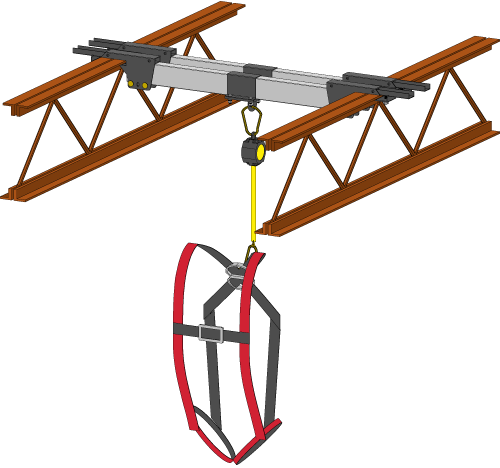

The installation of the Upper Deck Fall Protection Anchorage involves securing the unit to a stable surface, following the detailed guidelines provided in the installation manual to ensure proper load transfer and safety compliance.

What safety features does the anchorage system offer?

The safety features of the anchorage system include robust load transfer capabilities, engineered design for easy installation, and compliance with industry safety standards, ensuring reliable protection for workers during elevated tasks.

How does the anchorage system enhance worker safety?

The anchorage system enhances worker safety by providing a secure attachment point for fall protection gear, effectively distributing loads during a fall and minimizing injury risks. Its engineered design ensures reliability and ease of installation in various construction environments.

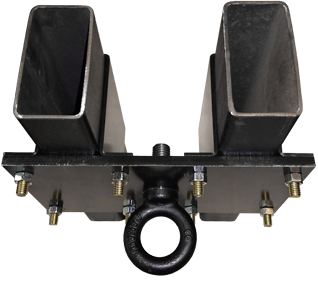

What materials are used in the anchorage system?

The materials used in the anchorage system include high-strength steel and durable aluminum, ensuring robust performance and longevity in demanding construction environments. These materials are specifically chosen for their ability to withstand heavy loads and harsh conditions.

Can the anchorage system be used on all roofs?

The anchorage system can be used on various roofs, but compatibility depends on the roof type and structure. It's essential to assess the specific roof conditions to ensure safe and effective installation.

What is the load capacity of the anchorage system?

The load capacity of the anchorage system is crucial for ensuring safety during elevated tasks. Our Upper Deck Fall Protection Anchorage system is designed to support loads of up to 5,000 pounds, providing reliable safety for workers in construction environments.

How do I maintain the anchorage system?

Maintaining the anchorage system involves regular inspections for wear, corrosion, and damage. Ensure all components are securely fastened and clean any debris that may obstruct functionality. Follow the manufacturer's guidelines for specific maintenance procedures.

Are there specific installation guidelines for the system?

Specific installation guidelines for the Upper Deck Fall Protection Anchorage system are provided to ensure proper setup and safety. It is crucial to follow these guidelines closely for optimal performance and compliance with safety standards.

What training is required for using the system?

The training required for using the Upper Deck Fall Protection Anchorage system includes understanding installation procedures, safety protocols, and proper usage techniques to ensure effective load transfer and worker safety during elevated tasks.

How does the anchorage system comply with safety regulations?

The compliance of the anchorage system with safety regulations is ensured through rigorous engineering standards and testing, meeting OSHA and ANSI guidelines for fall protection, thus guaranteeing reliable safety for workers in elevated tasks.

What are the installation costs for the anchorage system?

The installation costs for the anchorage system vary based on factors such as project size and complexity. For a precise estimate, please contact our sales team for a tailored quote.

How long does installation of the system take?

The installation of the Upper Deck Fall Protection Anchorage system typically takes a few hours, depending on the specific site conditions and requirements. Our engineered design allows for efficient setup, ensuring a quick and safe installation process.

Can the anchorage system be relocated easily?

The anchorage system can be relocated easily. Its engineered design allows for quick disassembly and reinstallation, making it versatile for various construction sites while maintaining safety and stability.

What accessories are available for the anchorage system?

The available accessories for the anchorage system include various connectors, safety harnesses, and extension lanyards, all designed to enhance the functionality and safety of the Upper Deck Fall Protection Anchorage.

How does the system perform in adverse weather conditions?

The performance of the system in adverse weather conditions is reliable and robust. It is engineered to withstand harsh elements, ensuring safety and stability even during rain, snow, or high winds, making it suitable for various outdoor applications.

What certifications does the anchorage system have?

The certifications of the anchorage system include compliance with OSHA and ANSI standards, ensuring it meets rigorous safety and performance criteria for fall protection in construction and industrial applications.

Are there any warranties for the anchorage system?

The warranties for the anchorage system are designed to ensure quality and reliability. Chicago Clamp Company provides a limited warranty that covers defects in materials and workmanship, offering peace of mind for our customers.

How can I order the anchorage system?

To order the anchorage system, you can visit our website and navigate to the product section for the Upper Deck Fall Protection Anchorage. From there, you can place your order directly online or contact our sales team for assistance.

What is the expected lifespan of the anchorage system?

The expected lifespan of the anchorage system is typically designed to last for a minimum of 10 years, depending on environmental conditions and maintenance practices. Regular inspections and proper care can further extend its longevity.

How does the anchorage system compare to competitors?

The anchorage system stands out against competitors due to its engineered design, ease of installation, and superior load transfer capabilities, ensuring enhanced safety and reliability for construction and industrial applications.

What are common installation mistakes to avoid?

Common installation mistakes to avoid include improper alignment of the anchorage system, neglecting to follow the manufacturer's guidelines, and failing to ensure secure attachment to the structure. Always double-check your setup to ensure maximum safety and effectiveness.

Can the anchorage system be used for multiple users?

The anchorage system can accommodate multiple users, provided it is installed according to the manufacturer's guidelines and safety standards. Always ensure that the total load does not exceed the system's rated capacity for optimal safety.

What is the best way to test the anchorage system?

The best way to test the anchorage system is to conduct a load test that simulates real-world conditions, ensuring it can safely support the intended loads and meet safety standards.

How does the anchorage system integrate with other safety equipment?

The integration of the anchorage system with other safety equipment is seamless, allowing for effective connection to harnesses, lanyards, and other fall protection gear. This ensures comprehensive safety for workers during elevated tasks.

What are the benefits of using engineered designs?

The benefits of using engineered designs include enhanced safety, improved efficiency, and optimal load transfer. These designs are tailored for specific applications, ensuring reliability and effectiveness in construction and industrial environments.

How can I access installation resources for the system?

Accessing installation resources for the Upper Deck Fall Protection Anchorage system is simple. You can find comprehensive installation guides and brochures on our website, specifically in the resources section dedicated to fall protection solutions.

What feedback have users provided about the system?

Users have provided positive feedback about the Upper Deck Fall Protection Anchorage system, highlighting its ease of installation, robust design, and effectiveness in enhancing safety during elevated tasks in construction environments.

Are there any case studies on the anchorage system?

Case studies on the anchorage system are available, showcasing real-world applications and effectiveness in enhancing worker safety during elevated tasks in construction and industrial settings. Please contact us for specific examples and detailed documentation.

How does the anchorage system improve productivity on site?

The anchorage system enhances productivity on site by providing secure and reliable fall protection, allowing workers to focus on their tasks without the distraction of safety concerns, ultimately leading to faster project completion and improved efficiency.