System Benefits

- Pre-Engineered and Tested System

- Adaptable and Cost Effective

- Rated for 1,000 lb. per Clamp/2,000 lb. per Header

- Proper Transfer of Loads to the Joist Top Chord

- Easily Installed Without Welding

Home >> Systems >> Header Systems >> Pipe Header System

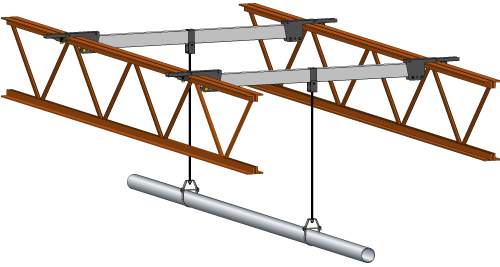

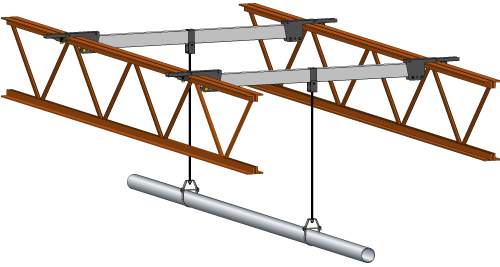

The Pipe Header System offers a range of features designed to enhance its performance and usability in various construction applications. With a robust 1,000 lb load capacity, this system is engineered to support significant weight, making it suitable for demanding environments.

Additional features include its adaptability to different structural configurations and the ability to install on HSS 4 x 2 tubing without the need for welding. This not only simplifies the installation process but also reduces labor costs and time, making it an efficient choice for construction professionals.

Proper installation is crucial for the performance and safety of the Pipe Header System. Users are advised to follow detailed installation guidelines to ensure that the system is secured correctly and meets all structural requirements.

It is recommended that installation be conducted under the supervision of a qualified structural engineer. This ensures that any modifications or additional loading are appropriately evaluated, maintaining the integrity and safety of the overall structure.

The Pipe Header System is versatile and can be utilized in a variety of construction and industrial applications. Its design makes it ideal for use in commercial buildings, warehouses, and manufacturing facilities, where reliable load-bearing support is essential.

Additionally, the system can be adapted for use in temporary structures and scaffolding, providing flexibility for contractors and engineers. This adaptability makes it a preferred choice in projects requiring both durability and efficiency.

Chicago Clamp Company is committed to providing exceptional customer support for users of the Pipe Header System. Our team is available to assist with inquiries, installation questions, and technical support to ensure that clients can make the most of their clamp systems.

In addition to direct support, we offer a wealth of resources, including detailed product specifications, demonstration videos, and engineering criteria. These resources are designed to empower users with the knowledge and tools necessary to effectively utilize our products in their projects.