Frequently Asked Questions

How to hang pants on clamp hanger?

Hanging pants on a clamp hanger involves simply grasping the waistband of the pants and placing it between the clamps. Ensure the clamps securely grip the fabric to prevent slipping and creasing.

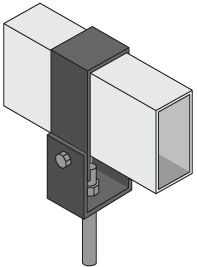

How to tighten a wooden clamp hanger?

Tightening a wooden clamp hanger involves securely fastening the clamp around the wooden structure. Use a wrench or screwdriver to turn the adjustment screw or bolt clockwise until the clamp firmly grips the wood, ensuring stability and support.

What type hanger clamp black pipe?

The type of hanger clamp suitable for black pipe is typically a U-bolt or a split-ring clamp, designed to securely support and stabilize the pipe within various construction and engineering applications.

How to build a quilt hanger clamp?

Building a quilt hanger clamp involves selecting sturdy materials, cutting them to size, and assembling the components to securely hold the quilt. Ensure the clamp allows for easy adjustments and is mounted properly for optimal support.

What materials are best for clamp hangers?

The best materials for clamp hangers are typically steel, stainless steel, and aluminum. These materials provide strength, durability, and resistance to corrosion, making them ideal for various construction and engineering applications.

How to choose the right clamp hanger?

Choosing the right clamp hanger involves assessing load capacity, installation requirements, and the specific application needs. Consider factors such as pipe size, material, and environmental conditions to ensure optimal support and flexibility in positioning.

What are the benefits of using clamp hangers?

The benefits of using clamp hangers include enhanced load capacity, ease of installation, and flexibility in positioning. These features make them ideal for reliable support in various construction and engineering applications, ensuring structural integrity and efficiency.

How to install a clamp hanger securely?

Installing a clamp hanger securely involves ensuring proper alignment, using the correct fasteners, and tightening them to the manufacturer's specifications. Always verify load capacity and position for optimal support in your application.

What sizes do clamp hangers come in?

Clamp hangers come in a variety of sizes to accommodate different pipe diameters and load requirements. Common sizes include options for standard pipes ranging from 1/2 inch to 12 inches, ensuring flexibility for various applications.

How to maintain a wooden clamp hanger?

Maintaining a wooden clamp hanger involves regularly inspecting it for signs of wear or damage, ensuring it is free from moisture, and applying a protective finish to prevent deterioration.

What is the load capacity of clamp hangers?

The load capacity of clamp hangers varies based on design and materials used, typically ranging from 500 to 2,000 pounds. Always consult the manufacturer's specifications for precise load ratings for specific applications.

How to adjust a clamp hanger for stability?

Adjusting a clamp hanger for stability involves ensuring it is securely fastened and properly aligned. Check the load distribution and tighten any loose components to prevent movement, ensuring optimal support for your pipe header system.

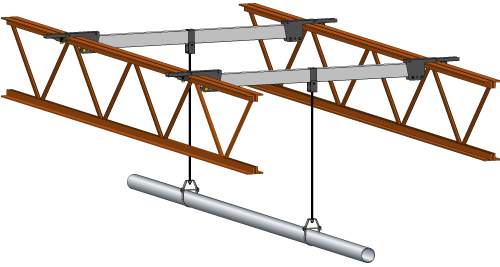

What applications are suitable for clamp hangers?

The applications suitable for clamp hangers include supporting pipe headers, HVAC systems, and electrical conduits, providing reliable structural support in various construction and engineering projects.

How to remove a clamp hanger safely?

Removing a clamp hanger safely involves first ensuring that any load supported by the hanger is properly secured or removed. Next, use appropriate tools to loosen and detach the hanger from its mounting surface, taking care to avoid sudden movements that could cause injury or damage.

What features to look for in clamp hangers?

The features to look for in clamp hangers include load capacity, material durability, ease of installation, adjustability for positioning, and compatibility with various pipe sizes to ensure reliable structural support in construction projects.

How to use clamp hangers for pipe support?

Using clamp hangers for pipe support involves securely attaching the hangers to structural elements, ensuring proper alignment and spacing for the pipes. Adjust the clamps to accommodate pipe size and load requirements for optimal support.

What types of materials can clamp hangers hold?

Clamp hangers can hold a variety of materials, including pipes, ducts, and conduits, typically made from metals like steel and aluminum, as well as some plastic materials, ensuring versatile support for different construction applications.

How to troubleshoot clamp hanger issues?

Troubleshooting clamp hanger issues involves inspecting for misalignment, ensuring proper load distribution, and checking for wear or damage. Adjust or replace components as needed to maintain optimal performance and stability in your pipe header systems.

What is the history of clamp hangers?

The history of clamp hangers dates back to the early 20th century, evolving from basic fastening methods to advanced designs that enhance structural support and flexibility in construction and engineering applications.

How to customize a clamp hanger design?

Customizing a clamp hanger design involves selecting specific dimensions, load capacities, and materials based on your project requirements. Collaborate with our engineering team to ensure optimal performance and flexibility tailored to your structural support needs.

What safety precautions to take with clamp hangers?

Safety precautions to take with clamp hangers include ensuring proper installation, regularly inspecting for wear and damage, and adhering to load capacity guidelines to prevent failures during use. Always follow manufacturer recommendations for safe operation.

How to find the right clamp hanger supplier?

Finding the right clamp hanger supplier involves researching reputable companies, evaluating their product range, checking customer reviews, and ensuring they offer the necessary support and specifications for your construction needs.

What innovations exist in clamp hanger technology?

Innovations in clamp hanger technology include advanced materials for increased durability, adjustable designs for flexible installation, and integrated vibration dampening features that enhance performance and safety in various construction applications.

How to compare different clamp hanger brands?

Comparing different clamp hanger brands involves evaluating their load capacities, material quality, installation features, and flexibility. Additionally, consider customer reviews and industry certifications to ensure reliability and performance in your construction projects.

What are common mistakes with clamp hangers?

Common mistakes with clamp hangers include improper load calculations, inadequate spacing, and neglecting to follow installation guidelines, which can lead to structural failures and safety hazards. Always ensure correct specifications and proper installation techniques for optimal performance.

How to ensure proper alignment with clamp hangers?

Ensuring proper alignment with clamp hangers involves accurately positioning the hangers to maintain consistent spacing and level across the pipe system. Regularly check alignment during installation to achieve optimal load distribution and structural integrity.

What are the environmental impacts of clamp hangers?

The environmental impacts of clamp hangers include potential resource depletion from material extraction and energy consumption during manufacturing. However, when designed for durability and recyclability, they can minimize waste and promote sustainability in construction projects.

How to integrate clamp hangers into construction projects?

Integrating clamp hangers into construction projects involves assessing load requirements, selecting suitable hanger types, and ensuring proper spacing during installation. This ensures structural support and flexibility in pipe header systems, enhancing overall project efficiency.

What are the best practices for using clamp hangers?

The best practices for using clamp hangers include ensuring proper load distribution, regularly inspecting for wear and tear, and following manufacturer guidelines for installation and spacing to maintain structural integrity and safety.

How to evaluate clamp hanger performance?

Evaluating clamp hanger performance involves assessing load capacity, installation ease, and flexibility in positioning. Consider these factors alongside compliance with engineering standards to ensure optimal functionality in your construction projects.