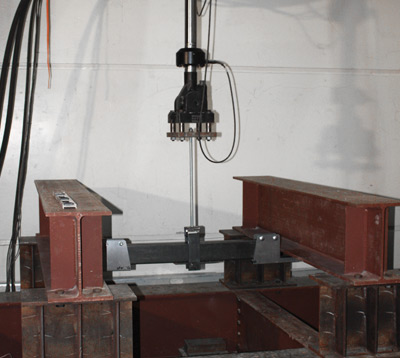

Independent Lab Testing & Load Capacity Tables for Clamp Systems

Each Chicago Clamp System® has been designed, and then rigorously tested by an independent engineering lab, to provide a product on which you can depend. Load tables derived by calculation and testing are conveniently organized in table form.

Suspension Clamp System

Live Load Capacity (pounds) vs. Span of Back-to-Back Angles 1-11

| Size of Each of an Angle Pair Longest angle leg is vertical | Span (feet) | |||||||||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| 2" x 2" x 3/16" | 1,690 | 1,123 | 821 | 635 | 511 | – | – | – | – | – | – | – | – | – |

| 2" x 2" x 1/4" | 2,000 | 1,459 | 1,088 | 856 | 693 | 569 | – | – | – | – | – | – | – | – |

| 2 1/2" x 2" x 3/16" | 2,000 | 1,707 | 1,237 | 956 | 769 | 635 | 536 | – | – | – | – | – | – | – |

| 2 1/2" x 2" x 1/4" | 2,000 | 2,000 | 1,691 | 1,313 | 1,061 | 882 | 748 | 643 | 528 | – | – | – | – | – |

| 3" x 2" x 3/16" | 2,000 | 2,000 | 1,645 | 1,270 | 1,020 | 842 | 708 | 604 | 521 | – | – | – | – | – |

| 3" x 2" x 1/4" | 2,000 | 2,000 | 2,000 | 1,791 | 1,446 | 1,200 | 1,061 | 873 | 759 | 665 | 587 | 520 | – | – |

| 3 1/2" x 2 1/2" x 1/4" | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 1,682 | 1,428 | 1,232 | 1,074 | 945 | 837 | 746 | 667 | 599 |

| 4" x 3" x 1/4" | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 1,873 | 1,618 | 1,414 | 1,246 | 1,106 | 988 | 886 | 798 |

| 5" x 3" x 1/4" | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 1,932 | 1,700 | 1,507 | 1,344 | 1,203 | 1,081 |

Table Notes 1-11

- Two Spanning Angles required per Suspension Clamp System, purchase though your local vendor.

- Angles are back-to-back, but spaced apart by Suspension Clamps.

- Allowable net load, per pair, may be located anywhere along the span. Weight of angles has been accounted for.

- Angle dimensions are listed “Vertical Leg” x “Horizontal Leg” x “Thickness”.

- No values below 500 lbs. are listed. Allowable loads have been limited to 2,000 lbs. maximum.

- Allowable loads are based on 36 ksi minimum yield steel and the AISC specifications.

- A single load equal to the tabulated capacity or multiple loads with a sum equal to the tabulated capacity is allowable.

- Live Load Capacities based on Safety Factor of 2.0.

- Loads in bold (528) are governed by deflection limit of Span/240; (e.g., 0.500″ for 10′ span).

- Tabulated values are based upon the additional bracing provided by Suspension Clamp System.

- Tabulated loads based on vertical loading only.

Joist Grip Framing Clamp System

Allowable Load (pounds) vs. Span a-h

| Tube Size (inches) | Load Type | Span (feet) | |||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| HSS 4" x 2" x 1/8" | concentrated | 2,000 | 2,000 | 2,000 | 2,000 | 1,801 | 1,572 | 1,318 | 1,067 |

| uniform | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 1,708 | |

| HSS 4" x 2" x 3/16" | concentrated | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 1,820 | 1,474 |

| uniform | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | 2,000 | |

Table Notes a-h

- Allowable concentrated load at middle of span. Allowable loads are net (weight of tube has been accounted for).

- Multiple loads, that are symmetrically placed and whose total equals the tabulated value, may be used.

- The reaction to each clamp bracket must be limited to a net value of the clamp’s charted capacity.

- Allowable loads have been limited to 2,000 lbs maximum.

- Allowable loads are based on 46 ksi minimum yield steel (A500, Gr. B), the AISC specification and a safety factor of 2.0.

- Loads in bold (1,067) are governed by applied-load deflection limit of Span / 240; (e.g., 0.50" for 10′ span).

- Tube’s 4" dimension is vertical. Span is horizontal.

- Tube weights: 4.75 lbs/ft for 1/8" wall, and 6.87 lbs/ft for 3/16" wall. Weights and thicknesses are nominal.

Tube Framing Clamp System

Live Load Capacity (pounds)

| Component Capacities | Download Positive | Uplift Negative |

| Allowable Load (pounds) | ||

| Joist Grip End Clamp | 1,000 | 1,000 |

| T-Bracket | 1,000 | 1,000 |

| InLine End Clamp | 1,000 | 1,000 |

| Girder Clamp | 1,000 | – |

| Cross Support Bracket | 1,000 | – |

Edge Tubes

Allowable Span vs. Load & Load-Type a-g

| Size of Rectangular Tube (inches); minor axis bending (a-g) | Max Load = 500 lbs. | Max Load = 1,000 lbs. | ||||||

| Concentrated | Uniform | Concentrated | Uniform | |||||

| (in.) | (ft. & in.) | (in.) | (ft. & in.) | (in.) | (ft. & in.) | (in.) | (ft. & in.) | |

| HSS 3" x 1.5" x 1/8" | 64 | 5′ – 4" | 81 | 6′ – 9" | 45 | 3′ – 9" | 57 | 4′ – 9" |

| HSS 3" x 1.5" x 3/16" | 73 | 6′ – 1" | 93 | 7′ – 9" | 52 | 4′ – 4" | 65 | 5′ – 5" |

| HSS 3" x 1.5" x 1/4" | 79 | 6′ – 7" | 100 | 8′ – 4" | 56 | 4′ – 8" | 70 | 5′ – 10" |

Table Notes a-g

- Short dimension of tube cross-section is vertical, parallel to load (minor axis bending).

- Allowable, net concentrated load, per tube, may be located anywhere in the span. Weight of tube has been accounted for.

- Allowable uniform load is the net loading on the tube. Weight of tube has been accounted for.

- allowable loads are based on 46 ksi minimum yield steel (ASTM A 500, Gr. B) and the AISC specification.

- All net (applied) loads are governed by deflection limit of Span / 240; (e.g., 0.250" for 5′ span)

- Tube-wall thicknesses are nominal. Minimum is 0.93 times nominal, per 2005 AISC specification.

- Allowable loads ("max" loads) arebased on a safety factor of 2.0.